Application industry

Machine tools, textile machines, printing, others

Technical specifications

█ Wide speed range

The low-frequency torque is large, which can realize the low-speed thread cutting and the finishing of more than 6000 revolutions.

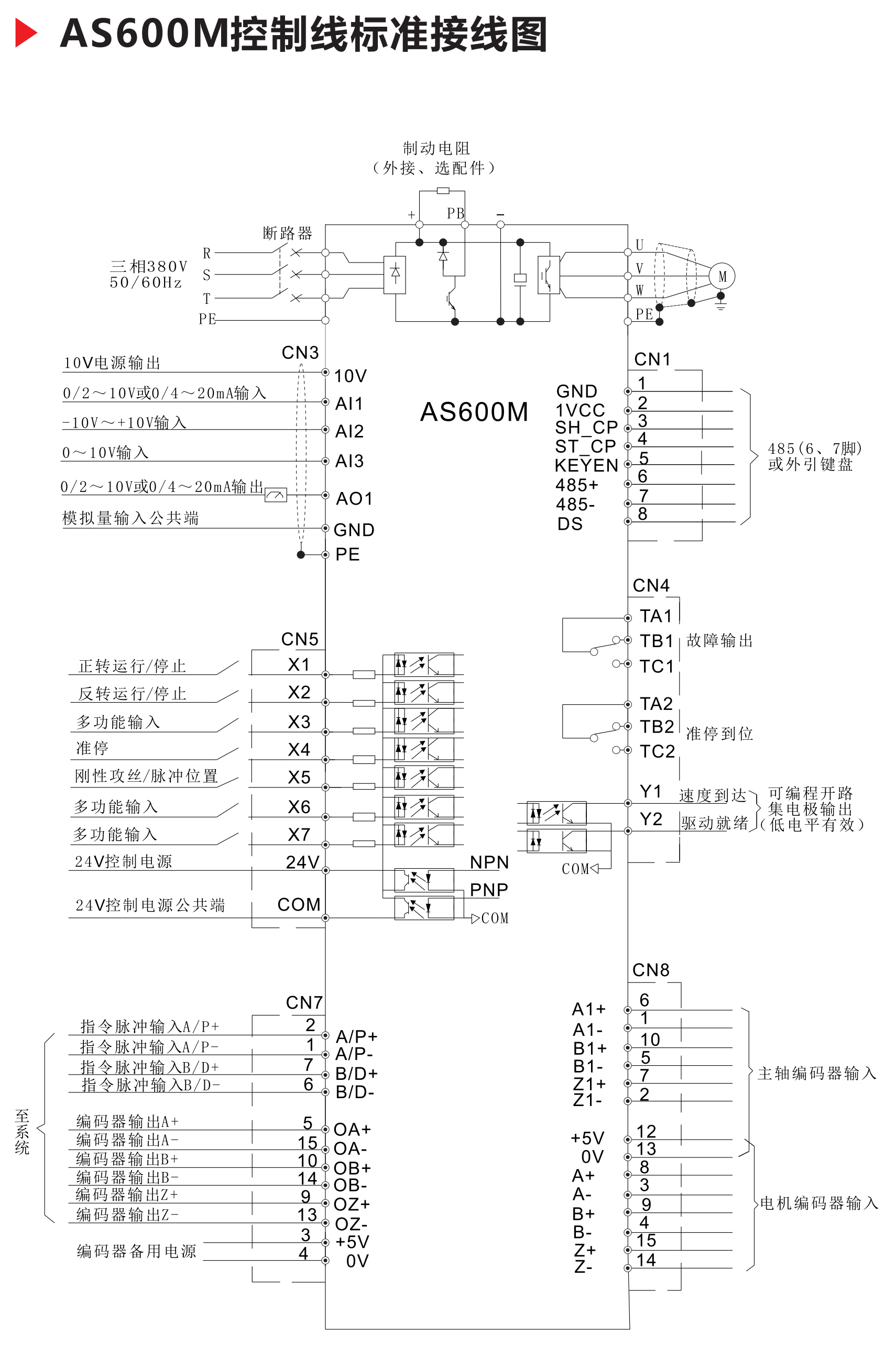

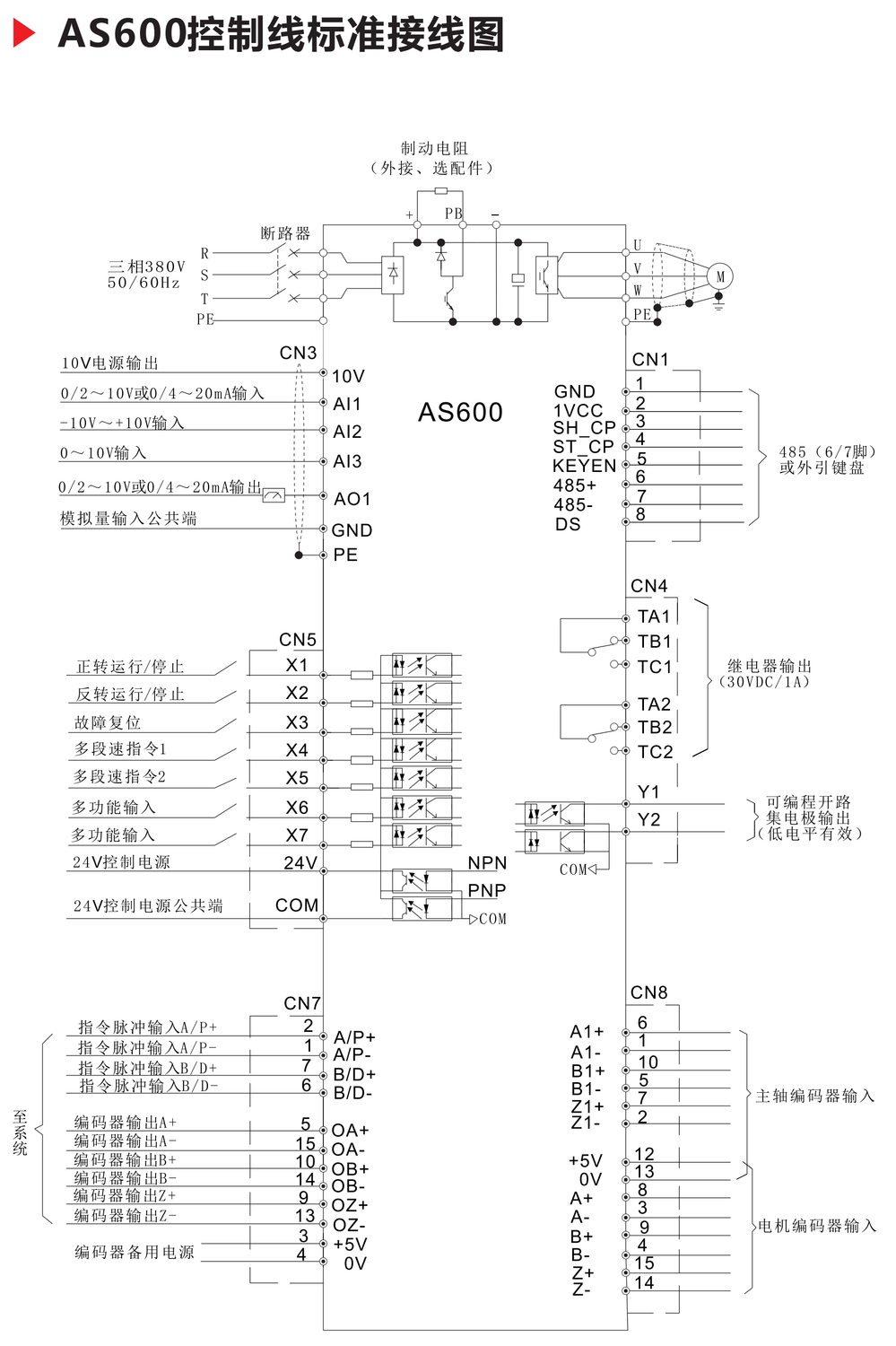

█ Rich interface

With pulse train and analog speed control function, multi-channel I/O, long-line drive encoder input and output, analog output and bus function.

█ Spindle exact stop function

S-curve stop, no overshoot under large inertia spindle, multi-position setting, easy to switch position.

█ Position mode

The feedforward is added to the position loop, the following error is small, and the pulse input filtering function can balance the operation under the condition of sudden input. Provide electronic gear ratio, position mode and speed can be switched at will, which can not only meet the C-axis function of the CNC system, but also meet other position synchronization and speed synchronization occasions.

█ Compatible with multiple CNC systems

Realize accurate stop of spindle, rigid tapping, low speed reaming, thread cutting, etc.

█ Other fields

Its wide speed range, fast response performance, low-frequency torque performance and position tracking can also be widely used in other fields, such as textile industry, plastic machine industry, carton packaging, woodworking machinery.

|

project |

description |

|

|

Output |

Maximum output voltage |

Three-phase 380V~440V, corresponding to input voltage |

|

Maximum output speed |

8000RPM |

|

|

Input |

Rated voltage and frequency |

Three-phase: 380~440V 50/60Hz |

|

Allow voltage fluctuation |

+10%,-15% |

|

|

Allow frequency fluctuations |

±5% |

|

|

Control characteristics |

control method |

正弦波PWM调制,全闭环矢量控制 |

|

Speed range |

1:5000 |

|

|

Speed control accuracy |

±1% |

|

|

Position control accuracy |

±1Pulse |

|

|

Frequency setting resolution |

Digital quantity 0.01HZ; analog quantity: unipolar, maximum output frequency/4096; bipolar, maximum output frequency/2048 |

|

|

Acceleration and deceleration time |

0~3600S to the highest output frequency

|

|

|

Braking method |

Energy consumption braking, built-in braking unit of 15KW and below |

|

|

Input and output interface |

Digital input |

7 optocoupler isolated inputs; input mode NPN, effective level optional |

|

Digital output |

3 optocoupler isolated outputs, 24V, 50mA |

|

|

Analog input |

2 channels: 0~10V, 0~20MA, -10V~+10V |

|

|

Analog output |

1 way, 0/2~10V 0/4~20MA optional |

|

|

Relay output |

1 way, a set of normally open and normally closed contacts; 250VAC/30VDC 1A |

|

|

Encoder input interface |

1: Maximum receiving pulse 300KHZ; line drive mode; RS422 standard; |

|

|

Pulse input interface |

1 channel: direction + pulse / quadrature pulse / CW + CCW |

|

|

Encoder output interface |

1 way: 1:1 frequency division output, line drive mode; RS422 standard |

|

|

Bus interface |

1 way: 485 bus |

|

|

Spindle function |

speed control |

Range: 0~8000RPM; Steering: positive and negative; Speed command: unipolar and bipolar analog quantity, pulse frequency, bus |

|

Quasi-stop control |

Accuracy of ±1Pulse; 8 positions can be selected with terminals |

|

|

Rigid tapping |

Can be interfaced with a variety of imported domestic systems, tapping error 2% |

|

|

other functions |

C axis control, thread cutting, electronic gear, reaming hole, zero speed lock

|

|

|

Protective function |

Overload protection |

With driver and motor overload protection function |

|

Overcurrent protection |

Hardware overcurrent protection

|

|

|

Undervoltage/overvoltage protection |

Bus voltage over 800V overvoltage protection, below 350V undervoltage protection |

|

|

Output short circuit protection |

When the output is shorted to ground, the alarm output |

|

|

Enabling environment |

Place of use |

Indoor, no corrosive gas |

|

temperature |

-10℃~40℃ |

|

|

humidity |

5~95RH (no condensation) |

|

|

Protection level |

IP20 |

|

Servo spindle motor specifications

|

power |

2.2~315KW |

Encoder |

Incremental type: pulse number 1024/2500, long-term drive, DC5V Resolver |

|

Input power |

Three-phase 220V/380V

|

||

|

Reference frequency |

50HZ;33.3HZ |

cooling method |

220V/380V 50HZ independent forced air cooling |

|

Maximum speed |

6000/8000r/min |

Motor output shaft |

With key; optical axis

|

|

Installation method |

B5 (flange installation), B3 (horizontal installation), B35 (flange + horizontal) |

Use environment

|

Below 1000 meters above sea level Ambient temperature -15~40℃ Relative humidity below 80% (no condensation) |

|

Stator part

|

F(155℃); H(180℃) insulation system; Manufacturing process of polymer insulating resin + vacuum negative pressure dipping paint |

||

|

Rotor part |

Half-key balance, R-level vibration, low noise imported bearings |