Please submit your message online, we will contact you as soon as possible!

Depot maintenance operation is the key link to ensure thes afe operation of rail transit. Although each subway company has formulated detailed and perfect rules and regulations and management measures to ensure the safety of maintenance operation, the current rules and regulations are completely implemented by people, and a large amount of human resources are invested, which is not efficient and reliable.

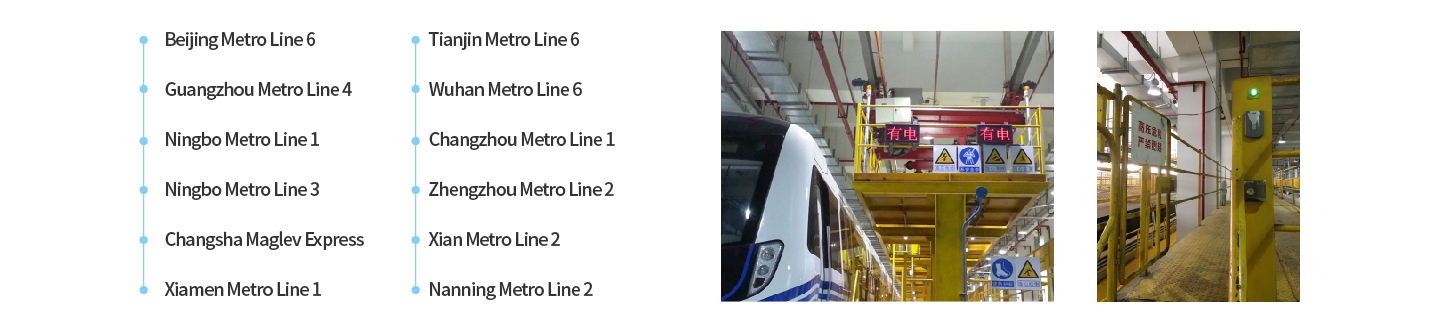

Considering the power supply operation and maintenance safety of the depot, the safety interlocking management system of depot maintenance operation has established a programmed, networked, visualized and standardized safety management and control platform in combination with the depot management measures. The system makes full use of various information detection, computer logic processing, safety interlock and other technical measures to effectively prevent accidents caused by staff negligence, mentalfatigue, poor contact and other factors, and ensure the safety of personnel and equipment.

● Realize the safety management and control of the whole process of power stop and transmission operation and on-site maintenance operation in the depot area;

● It can collect the real-time status and operation information of the equipment related to the operation in the depot and display it in the background.

● The field operation process is transformed into computer logic control rules, and the system makes overall logic judgment and control according to the field real-time state.

● Before the actual operation, it can simulate the billing, generate the operation sequence in line with the error prevention logic, and transmit it to the handheld terminal, and the operator can take the handheld terminal for operation to ensure the correct operation process.

● According to different requirements, ground wire management or power test grounding cabinet can be adopted to realize the safety and standard management of overhead contact system grounding operation in the reservoir area;

● Real time detection of live state of catenary in the reservoir area, and visual display on the field led and DCC inspection and adjustment workstation.

● Realize the compulsory power test function before the grounding operation of the overhead contact system in the reservoir area, and prevent the live grounding misoperation of the overhead contact system.

● Realize the video linkage monitoring of DCC inspection and adjustment on the operation process of power cut and transmission and maintenance operation in the reservoir area.

● By means of LED, warning light and voice alarm, it can provide visual display and sound light warning for the operation status of catenary and maintenance platform, so as to ensure the safe operation of maintenance personnel.

The safety interlock management and control of catenary power stop and transmission, power test, grounding, operation on stage and other links are realized to ensure personal and equipment safety.

Remote real-time monitoring depot operation and related equipment status, intuitive control of the scene.

Using remote grounding, intelligent door control, electronic billing and other automation technology, greatly improve the efficiency of operation.

The live state of the catenary can be detected and monitored online, and various ways such as warning lights and voice broadcast can be used to realize all-round safety warning for the on-site personnel.